Difference between revisions of "Powering the station"

Convair880 (talk | contribs) m (Starboard solar wiring has been fixed, increasing the array's maximum output by ~20.000 W.) |

Convair880 (talk | contribs) m (The "analyzer" now has an appropriate prefix.) |

||

| Line 63: | Line 63: | ||

Gas has some important properties, pressure temperature and heat capacity. | Gas has some important properties, pressure temperature and heat capacity. | ||

*Pressure directs the gas flow from higher to lower pressure pipe segments. If pressure it too high in a pipe, pumps will not be able to move gas, and power output will drop. <br>Above 17,000 kPa, pipes have a chance to burst! Check the meters, and use your [[PDA]] or an [[Engineering Objects#Analyzer|analyzer]] on a pipe to read its pressure. | *Pressure directs the gas flow from higher to lower pressure pipe segments. If pressure it too high in a pipe, pumps will not be able to move gas, and power output will drop. <br>Above 17,000 kPa, pipes have a chance to burst! Check the meters, and use your [[PDA]] or an [[Engineering Objects#Analyzer|atmospheric analyzer]] on a pipe to read its pressure. | ||

*Temperature causes gas to increase or decrease in pressure. Very little gas when heated can reach gigantic pressure. Conversely, gas in the cold loop will most often be at a low pressure. | *Temperature causes gas to increase or decrease in pressure. Very little gas when heated can reach gigantic pressure. Conversely, gas in the cold loop will most often be at a low pressure. | ||

Revision as of 11:18, 21 March 2015

There are two distinct ways to supply the station with electricity, which can either be used exclusively or in combination with each other. The solar arrays are efficient and simple, yet leave no room for experimentation. In contrast, there are probably as many different engine setups as there are engineers.

The solar arrays

Solar arrays are not a complicated affair and generate a decent amount of electricity when operating properly. By default, they provide the station with sufficient power and generally do not require any maintenance. They're also a single wire snip away from sabotage, so they should not be relied on completely in lieu of the generator if possible.

How it all works

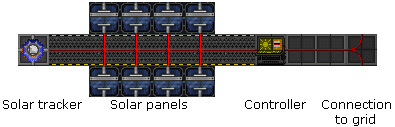

Each array is a fully automatic and for the most part self-contained system. It consists of:

- The solar tracker, which tracks the location of the sun.

- Solar panels to generate electricity.

- The control terminal, which aligns the panels to the sun.

- Regular wiring then feeds the amount of power currently generated by the array to the station grid.

Auto-tracking doesn't work when there is no continuous connection between the tracker and control terminal. Damaged wiring will also prevent panels from rotating automatically, as they can't receive commands from the computer.

Note: The computer is tied to the APC's equipment setting. If the APC has been switched off or drained at any point, it is necessary to reset the tracking program from Auto to Off and back to Auto.

| Array | Image | Peak output | Info |

|---|---|---|---|

| Aft (bridge maint.) |

|

~90.000 W | The smallest and thus least powerful array. It generates around 54000 W on average. |

| Port (catering maint.) |

|

~120.000 W | Average output is about 85000 W. |

| Starboard (near tech storage) |

|

~120.000 W | Average output is about 85000 W |

Keep in mind that the sun will always be moving in relation to the station, which means that the amount of electricity generated by each array won't be constant. For this reason, it's also best to leave the control terminal on the default settings (i.e. Auto) unless you want to babysit the arrays and rotate them manually. This will ensure that there is almost always enough juice available to keep the APCs supplied, even if a single array may contribute only 25.000 W to the total number. Typically, the station demands circa 130.000 W.

The thermoelectric generator

How it all works

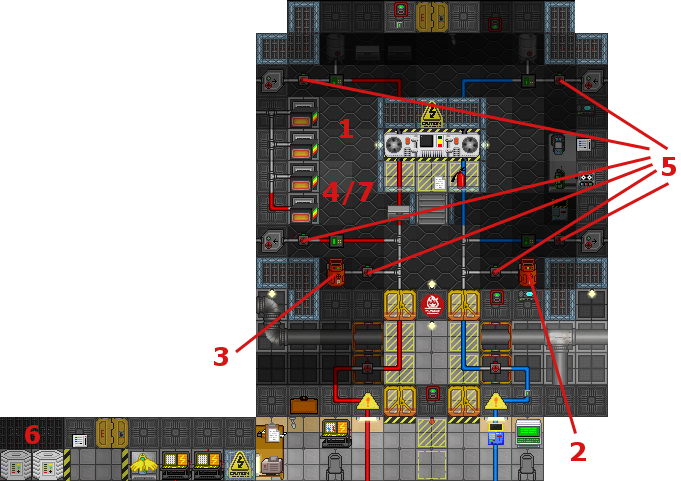

The engine has three segments:

- The hot loop, where heat is generated by heating gas in the furnaces, the combustion chamber or using a mixture that creates fire right in the pipes.

- The cold loop that absorbs heat and radiates to space.

- The generator which transfers heat from the hot to the cold loop and produces power.

Four passive gates around the loop keep the gas flowing.

Each primary canister hookup has its own pump, to increase or decrease the speed of gas injection of into a loop.

The vents at both sides of engineering allow you to remove excessive pressure or scrub a loop of unwanted gas.

Gas

Gas has some important properties, pressure temperature and heat capacity.

- Pressure directs the gas flow from higher to lower pressure pipe segments. If pressure it too high in a pipe, pumps will not be able to move gas, and power output will drop.

Above 17,000 kPa, pipes have a chance to burst! Check the meters, and use your PDA or an atmospheric analyzer on a pipe to read its pressure.

- Temperature causes gas to increase or decrease in pressure. Very little gas when heated can reach gigantic pressure. Conversely, gas in the cold loop will most often be at a low pressure.

- Heat capacity is different for each gas, it determines how quickly a gas can absorb and transfer heat.

Any gas can be used as a medium in both pipe loops; and each gas has a different ability to retain heat or transfer it more quickly. Generally, safer gases will yield much lower power outputs.

Experimenting with different gas in each loop will let you discover which combinations work best, and how to control the most dangerous gas mixtures.

Pressure

The engine can be efficiently run on very small quantities of gas. Filling the pipes with entire canisters of gas will increase the chance of pressure issues. Injecting small quantities of gas in the loops and the combustion chamber over time reduces waste and allows for very high power outputs.

Too high pressure inside a pipe will cause it to fracture and leak gas. A broken pipe can be repaired by welding.

Pressure imbalances that stop the correct flow of gas can be controlled by venting gas (either to a canister, or to space). Venting is more effective when gas flow is temporarily blocked by shutting down the proper valve.

An example to get you started

The following setup is safe, straight-forward and almost maintenance-free. If it is your first day on the job, it may be useful as a starting point, to observe how the engine behaves under load. Or perhaps you're just interested in something nice and easy to keep the lights on.

- 1. Dump some char ore in the furnaces.

- You can find char ore in the metal boxes in the storage room northeast of the engine chamber.

- 2. Connect one tank of plasma to the cold loop auxiliary port.

- You can find plasma canisters in the same storage room. You need to pull the tank atop the port, then lock it into place with a wrench.

- 3. For the hot loop, take a canister of plasma and connect it to the auxiliary port on the opposite side.

- 4. Activate the furnaces.

- It is imperative that you do this before the next step. Doing it the other way around may trigger a glitch and render the setup useless.

- 5. Open the corresponding valves.

- 6. Set both SMES units to 200.000 input and 100.000 output.

- 7. Come back ~30 min later and load more ore in the furnaces.

If you follow these steps correctly, the engine should generate a steady ~1.3 MW for the duration of a typical shift. Plasmastone, when available, can be used to increase the output.