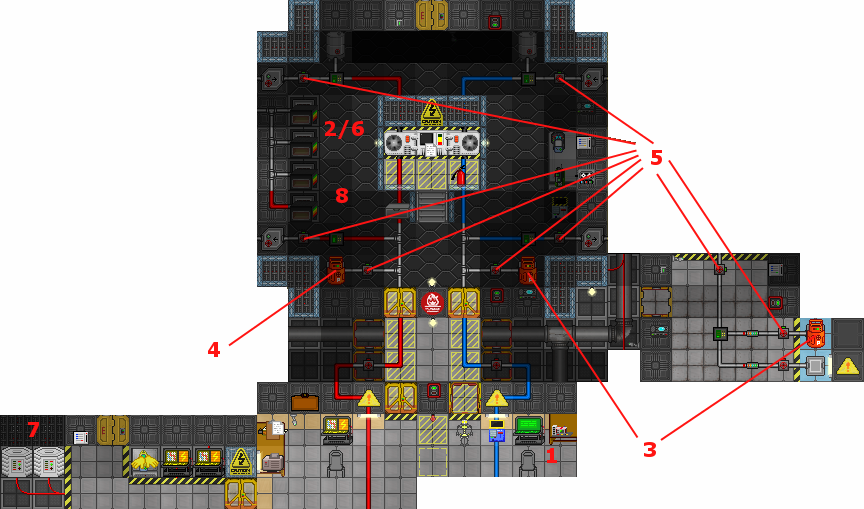

Powering the station: Difference between revisions

Convair880 (talk | contribs) m New image: updated engine schematic.Of course I ended up doing it myself... |

|||

| Line 1: | Line 1: | ||

[[ | [[Image:UpdatedEngineSchematic.png|1000px]]<br> | ||

==How it all works== | ==How it all works== | ||

Revision as of 03:50, 8 May 2014

File:UpdatedEngineSchematic.png

How it all works

The engine has three segments:

- The hot loop, where heat is generated by heating gas in the furnaces, the combustion chamber or using a mixture that creates fire right in the pipes.

- The cold loop that absorbs heat and radiates to space.

- The generator which transfers heat from the hot to the cold loop and produces power.

Four passive gates around the loop keep the gas flowing.

Each primary canister hookup has its own pump, to increase or decrease the speed of gas injection of into a loop.

The vents at both sides of engineering allow you to remove excessive pressure or scrub a loop of unwanted gas.

Gas

Gas has some important properties, pressure temperature and heat capacity.

- Pressure directs the gas flow from higher to lower pressure pipe segments. If pressure it too high in a pipe, pumps will not be able to move gas, and power output will drop.

Above 17,000 kPa, pipes have a chance to burst! Check the meters, and use your PDA or an analyzer on a pipe to read its pressure.

- Temperature causes gas to increase or decrease in pressure. Very little gas when heated can reach gigantic pressure. Conversely, gas in the cold loop will most often be at a low pressure.

- Heat capacity is different for each gas, it determines how quickly a gas can absorb and transfer heat.

Any gas can be used as a medium in both pipe loops; and each gas has a different ability to retain heat or transfer it more quickly. Generally, safer gases will yield much lower power outputs.

Experimenting with different gas in each loop will let you discover which combinations work best, and how to control the most dangerous gas mixtures.

Pressure

The engine can be efficiently run on very small quantities of gas. Filling the pipes with entire canisters of gas will increase the chance of pressure issues. Injecting small quantities of gas in the loops and the combustion chamber over time reduces waste and allows for very high power outputs.

Too high pressure inside a pipe will cause it to fracture and leak gas. A broken pipe can be repaired by welding.

Pressure imbalances that stop the correct flow of gas can be controlled by venting gas (either to a canister, or to space). Venting is more effective when gas flow is temporarily blocked by shutting down the proper valve.

An example to get you started

The following setup is safe, straight-forward and almost maintenance-free. If it is your first day on the job, it may be useful as a starting point, to observe how the engine behaves under load. Or perhaps you're just interested in something nice and easy to keep the lights on.

- 1. Set all engine pumps to one.

- 2. Dump some char ore in the furnaces. (You can find char ore in the metal boxes in the storage room northeast of the engine chamber.)

- 3. Connect one tank of plasma to the cold loop and another one to the engine room's auxiliary port. (You can find plasma canisters in the same storage room. Don't confuse them with N2 tanks, which have a similar color. You need to pull them into place on their ports, then lock them into place with a wrench. You should have a wrench in the toolbox you started with.)

- 4. For the hot loop, take a canister of plasma and connect it to the auxiliary port on the opposite side.

- 5. Open the corresponding valves.

- 6. Activate the furnaces.

- 7. Set both SMES units to 200.000 input and 100.000 output.

- 8. Come back ~30 min later and load more ore in the furnaces.

If you follow these steps correctly, the engine should generate a steady ~1.3 MW for the duration of a typical shift. Plasmastone, when available, can be used to increase the output.