Difference between revisions of "User:Vortex1942/Automating the TEG"

Vortex1942 (talk | contribs) (→Pumps) |

Vortex1942 (talk | contribs) (Replace RegEx with Signal Splitters) |

||

| (11 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

''See Also:'' | |||

| | * ''[[Packets]]'' | ||

* ''[[MechComp]]'' | |||

* ''[[Thermoelectric_Generator|Thermoelectric Generator]]'' | |||

=== | = Controllable Devices = | ||

Tired of watching the TEG constantly?, Ever want to just outsource your job to a computer? Well this is for you. | |||

These devices are able to recieve signals from MechComp to control the engine/toxins. | |||

== Wireless Devices == | |||

=== Frequencies === | |||

Most Atmos devices will use these frequencies. | |||

* Engineering: 122.5 | * Engineering: 122.5 | ||

* Science: 122.9 | * Science: 122.9 | ||

==== | * Security: ███ | ||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 30%; | |||

|'''Pump''' | |||

|- | |||

| | |||

=== Pump === | |||

Powered down pumps do not transfer gas, Meaning they can be used as controllable Electronic Valves, | |||

'''<big>Commands</big>''' | |||

* '''WARNING''': Omitting <code>tag</code> will cause commands to be sent to '''ALL''' pumps | * '''WARNING''': Omitting <code>tag</code> will cause commands to be sent to '''ALL''' pumps | ||

| Line 35: | Line 46: | ||

** <code>command</code>: <code>broadcast_status</code> | ** <code>command</code>: <code>broadcast_status</code> | ||

'''<big>Pump Status</big>''' | |||

The following is transmited whenever a pump recieves are command | The following is transmited whenever a pump recieves are command | ||

* <code>tag</code>: <code>(Pump Name)</code> | * <code>tag</code>: <code>(Pump Name)</code> | ||

| Line 43: | Line 54: | ||

* <code>address_tag</code>: <code>pumpcontrol</code> | * <code>address_tag</code>: <code>pumpcontrol</code> | ||

'''<big>Packet Examples</big>''' | |||

Purge Hotloop: | Purge Hotloop: | ||

* <code>tag=Hot Loop Purge Pump;command=power_on</code> | * <code>tag=Hot Loop Purge Pump;command=power_on</code> | ||

| Line 55: | Line 63: | ||

Set Pressure: | Set Pressure: | ||

* <code>tag=Hot Loop Purge Pump;command=set_target_pressure;parameter=5000</code> | * <code>tag=Hot Loop Purge Pump;command=set_target_pressure;parameter=5000</code> | ||

|} | |||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 30%; | |||

* <code>tag= | |'''Gas Mixer''' | ||

|- | |||

| | |||

=== Gas Mixer === | |||

Did I hear you say "Adjustable combustion chamber temperatures?" | |||

* '''NOTE''': Unfortunately I have not been able to tap into status reports from mixers | |||

'''<big>Commands</big>''' | |||

* Toggle Power | |||

** <code>command</code>: <code>toggle_pump</code> | |||

** <code>parameter</code>: <code>power_on</code> or <code>power_off</code> | |||

** <code>tag</code>: <code>(Mixer Name)</code> | |||

* Set gas ratio | |||

** '''NOTE''': <code>parameter</code> value is Input 1 ratio only ie. 66 = 66:33 | |||

** <code>command</code>: <code>set_ratio</code> | |||

** <code>parameter</code>: <code>(0-100 Number)</code> | |||

** <code>tag</code>: <code>(Mixer Name)</code> | |||

* Set gas pressure | |||

** '''NOTE''': <code>parameter</code> is an uncapped value | |||

** <code>command</code>: <code>set_ratio</code> | |||

** <code>parameter</code>: <code>(Target Air Pressure)</code> | |||

** <code>tag</code>: <code>(Mixer Name)</code> | |||

'''<big>Packet Examples</big>''' | |||

Set Ratio to 66:33: | |||

* <code>tag=engine_combust_control; command=set_ratio; parameter=66</code> | |||

Set Pressure to 75kPa: | |||

* <code>tag=engine_combust_control; command=set_pressure; parameter=75</code> | |||

Turn off mixer: | |||

* <code>tag=engine_combust_control; command=toggle_pump; parameter=power_off</code> | |||

|} | |} | ||

== MechComp Devices == | |||

Connecting the generator and pressure will require using you multitool on them and selecting "Connect Component" | |||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 30%; | |||

|'''The Generator''' | |||

|- | |||

| | |||

=== The Generator === | |||

Ever wanted to boast about the engine output to the crew? Well now you can do it automatically! | |||

'''<big>Outputs</big>''' | |||

* <code>power</code>: <code>(Unformatted power output)</code> | |||

* <code>powerfmt</code>: <code>(Formatted power output, 2.21 GW)</code> | |||

'''<big>Signal Fields</big>''' | |||

* Raw Signal: <code>power=3.84698e+06&powerfmt=3.847 MW</code> | |||

* <code>power</code>: <code>(Raw Power Output)</code>; Example: <code>3.84698e+06</code> | |||

* <code>powerfmt</code>: <code>(Formatted Power Output)</code>; Example: <code>3.847 MW</code> | |||

Use a WiFi signal splitter component to grab the values of these fields | |||

|} | |||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 30%; | |||

|'''Pressure Meter''' | |||

|- | |||

| | |||

=== Pressure Meter === | |||

The main source of data for engine automation. | |||

'''<big>Signal Fields</big>''' | |||

* Raw Signal: <code>pressure=3410.27&temperature=20462.7</code> | |||

* <code>pressure</code>: <code>(Pipe Pressure)</code>; Example: <code>3410.27</code> | |||

* <code>temperature</code>: <code>(Pipe temperature)</code>; Example: <code>20462.7</code> | |||

Use a WiFi signal splitter component to grab the values of these fields | |||

|} | |||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 30%; | |||

|'''Circulators (Blowers) ''' | |||

|- | |||

| | |||

=== Circulators (Blowers) === | |||

Useful for optimizing the target pressure on the blowers. | |||

'''<big>Inputs</big>''' | |||

* '''NOTE''': <code>parameter</code> has a max value of 100000kPa | |||

* <code>Toggle Active</code>: <code>(Pipe Pressure)</code> | |||

* <code>Set Target Pressure</code>: <code>(Pipe pressure)</code> | |||

|} | |||

= Example Contraptions = | |||

Use these examples to help get started with making your own controllers. | |||

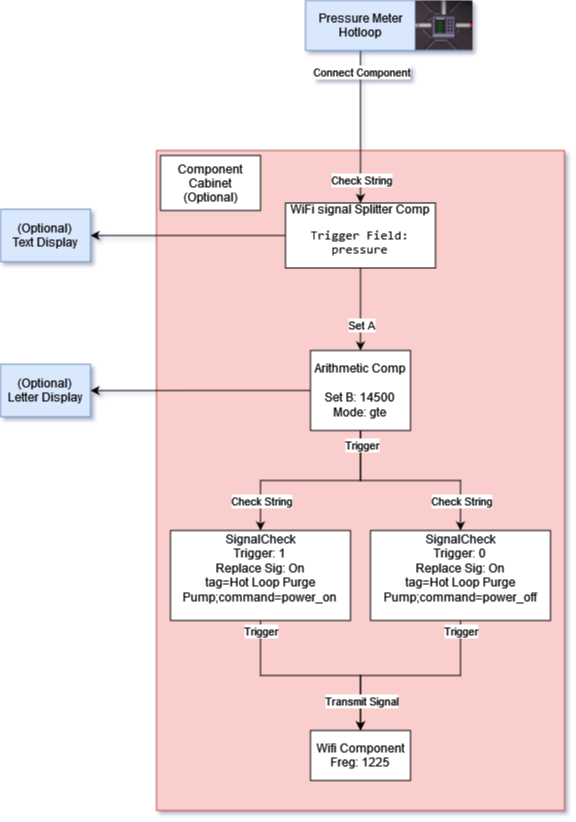

=== Hot Loop Auto-purge === | |||

Tired of your hot loop pipes rupturing and plasma flooding engineering? Well this is for you! | |||

What it does? | |||

* When the meter pressure is above <code>14500</code>, the Arithmetic will send a 1 to both Signal Checks, Signal Check A then sends a WiFi packet to turn on the purge pump. | |||

Mechlab Shopping List: | |||

* 1x WiFi Signal Splitter Component. | |||

* 1x Arithmetic Component. | |||

* 2x Signal Check Component. | |||

* 1x WiFi Component. | |||

Optional: | |||

* Letter Display (See if the pump is currently on). | |||

* Text Display (Show off your current pipe pressure). | |||

* Component Cabinet. | |||

To Assemble (Or see wiring diagram below): | |||

# Place and wrench components, Optionally: In a component cabinet. | |||

# Interact with a multitool on a pressure meter, select "Connect Component". | |||

#* Use a pressure meter that is directly connecting to the furnaces/combustion chamber, Avoid meters on the output end of pipes. | |||

# Interact with the WiFi signal splitter Component, select "Check String". | |||

# Interact with the multitool to finish pairing. | |||

# On the WiFi signal splitter Component set "trigger field" to <code>pressure</code>. | |||

# Hold your multitool, Click and drag from the WiFi signal splitter Component to the Arithmetic Component. | |||

#* Select "Trigger" then "Set A". | |||

# On Signal Check A, set: "Set B" = <code>14500</code>; "Mode" = <code>gte</code>. | |||

#* This compares if A >= B, B is your max pressure (Change "Mode" to lte to make this setup do something when the pressure is low, Eg. Turn on an inlet pump). | |||

# On the Arithmetic component set "Set B" to <code>14500</code> (This is your Auto-purge pressure). | |||

# On the Arithmetic component set "Mode" to <code>gte</code> (Greather than or Equal) (Additionally, this is where you could turn this into an Auto-filler if the pressure is low). | |||

# Hold your multitool, Click and drag from the Arithmetic Component to both Signal Check Components. | |||

# On Signal Check A, set: "Send Signal" = <code>tag=Hot Loop Purge Pump;command=power_on</code>; "Trigger String" = <code>1</code>; Replace Signal = <code>On</code>. | |||

# On Signal Check B, set: "Send Signal" = <code>tag=Hot Loop Purge Pump;command=power_off</code>; "Trigger String" = <code>'''0'''</code>; Replace Signal = <code>On</code>. | |||

# Hold your multitool, Click and drag both Signal Check Components to both the WiFi Component. | |||

# On the WiFi component, set: "Frequency" = <code>1255</code>. | |||

# Open the manual hot loop purge valve. | |||

#* If multiple purge lines, use the one before the engine inlet. | |||

# Kick back and relax? | |||

{|class="wikitable mw-collapsible mw-collapsed plainrowheaders" style="width: 50%; | |||

|'''Wiring Diagram''' | |||

|- | |||

| | |||

[[File:AutoTEGControllerWiring.png]] | |||

|} | |||

=== Engine Power Output Display === | |||

Automagically brag about your engine output | |||

Mechlab Shopping List: | |||

* 1x WiFi Signal Splitter Component. | |||

* 1x Text Display. | |||

Optional: | |||

* 1x Signal Build Component | |||

To Assemble (Or see wiring diagram below): | |||

# Place and wrench components. | |||

# Interact with a multitool on the generator, select "Connect Component". | |||

# Interact with the WiFi Signal Splitter Component, select "Check String". | |||

# Interact with the multitool to finish pairing. | |||

# On the WiFi Signal Splitter Component set "trigger field" to <code>powerfmt</code>. | |||

# Hold your multitool, Click and drag from the WiFi Signal Splitter Component to the Text Display. | |||

* Optional: Use a signal build component to add extra text to your display. | |||

=== Contraption Ideas === | |||

* Using inlet pumps, add gas to hotloop if the pipe pressure is low. | |||

* Add oxygen to hotloop every 10 seconds. | |||

* Broadcast engine output to the Engineering radio, Or general radio :) | |||

** Or Low/High Pressure alerts that are sent to radio or PDA. | |||

* Set blowers to the ideal pressure value based on inlet/outlet pressure | |||

< | =Supplementary Video= | ||

<youtube>wEFzcmtATMM</youtube> | |||

---- | |||

Latest revision as of 22:44, 15 December 2023

See Also:

Controllable Devices

Tired of watching the TEG constantly?, Ever want to just outsource your job to a computer? Well this is for you.

These devices are able to recieve signals from MechComp to control the engine/toxins.

Wireless Devices

Frequencies

Most Atmos devices will use these frequencies.

- Engineering: 122.5

- Science: 122.9

- Security: ███

| Pump |

PumpPowered down pumps do not transfer gas, Meaning they can be used as controllable Electronic Valves, Commands

Pump Status The following is transmited whenever a pump recieves are command

Packet Examples Purge Hotloop:

Check All Pumps:

Set Pressure:

|

| Gas Mixer |

Gas MixerDid I hear you say "Adjustable combustion chamber temperatures?"

Commands

Packet Examples Set Ratio to 66:33:

Set Pressure to 75kPa:

Turn off mixer:

|

MechComp Devices

Connecting the generator and pressure will require using you multitool on them and selecting "Connect Component"

| The Generator |

The GeneratorEver wanted to boast about the engine output to the crew? Well now you can do it automatically! Outputs

Signal Fields

Use a WiFi signal splitter component to grab the values of these fields |

| Pressure Meter |

Pressure MeterThe main source of data for engine automation. Signal Fields

Use a WiFi signal splitter component to grab the values of these fields |

| Circulators (Blowers) |

Circulators (Blowers)Useful for optimizing the target pressure on the blowers. Inputs

|

Example Contraptions

Use these examples to help get started with making your own controllers.

Hot Loop Auto-purge

Tired of your hot loop pipes rupturing and plasma flooding engineering? Well this is for you!

What it does?

- When the meter pressure is above

14500, the Arithmetic will send a 1 to both Signal Checks, Signal Check A then sends a WiFi packet to turn on the purge pump.

Mechlab Shopping List:

- 1x WiFi Signal Splitter Component.

- 1x Arithmetic Component.

- 2x Signal Check Component.

- 1x WiFi Component.

Optional:

- Letter Display (See if the pump is currently on).

- Text Display (Show off your current pipe pressure).

- Component Cabinet.

To Assemble (Or see wiring diagram below):

- Place and wrench components, Optionally: In a component cabinet.

- Interact with a multitool on a pressure meter, select "Connect Component".

- Use a pressure meter that is directly connecting to the furnaces/combustion chamber, Avoid meters on the output end of pipes.

- Interact with the WiFi signal splitter Component, select "Check String".

- Interact with the multitool to finish pairing.

- On the WiFi signal splitter Component set "trigger field" to

pressure. - Hold your multitool, Click and drag from the WiFi signal splitter Component to the Arithmetic Component.

- Select "Trigger" then "Set A".

- On Signal Check A, set: "Set B" =

14500; "Mode" =gte.- This compares if A >= B, B is your max pressure (Change "Mode" to lte to make this setup do something when the pressure is low, Eg. Turn on an inlet pump).

- On the Arithmetic component set "Set B" to

14500(This is your Auto-purge pressure). - On the Arithmetic component set "Mode" to

gte(Greather than or Equal) (Additionally, this is where you could turn this into an Auto-filler if the pressure is low). - Hold your multitool, Click and drag from the Arithmetic Component to both Signal Check Components.

- On Signal Check A, set: "Send Signal" =

tag=Hot Loop Purge Pump;command=power_on; "Trigger String" =1; Replace Signal =On. - On Signal Check B, set: "Send Signal" =

tag=Hot Loop Purge Pump;command=power_off; "Trigger String" =0; Replace Signal =On. - Hold your multitool, Click and drag both Signal Check Components to both the WiFi Component.

- On the WiFi component, set: "Frequency" =

1255. - Open the manual hot loop purge valve.

- If multiple purge lines, use the one before the engine inlet.

- Kick back and relax?

| Wiring Diagram |

Engine Power Output Display

Automagically brag about your engine output

Mechlab Shopping List:

- 1x WiFi Signal Splitter Component.

- 1x Text Display.

Optional:

- 1x Signal Build Component

To Assemble (Or see wiring diagram below):

- Place and wrench components.

- Interact with a multitool on the generator, select "Connect Component".

- Interact with the WiFi Signal Splitter Component, select "Check String".

- Interact with the multitool to finish pairing.

- On the WiFi Signal Splitter Component set "trigger field" to

powerfmt. - Hold your multitool, Click and drag from the WiFi Signal Splitter Component to the Text Display.

- Optional: Use a signal build component to add extra text to your display.

Contraption Ideas

- Using inlet pumps, add gas to hotloop if the pipe pressure is low.

- Add oxygen to hotloop every 10 seconds.

- Broadcast engine output to the Engineering radio, Or general radio :)

- Or Low/High Pressure alerts that are sent to radio or PDA.

- Set blowers to the ideal pressure value based on inlet/outlet pressure

Supplementary Video