Powering the station

How It All Works

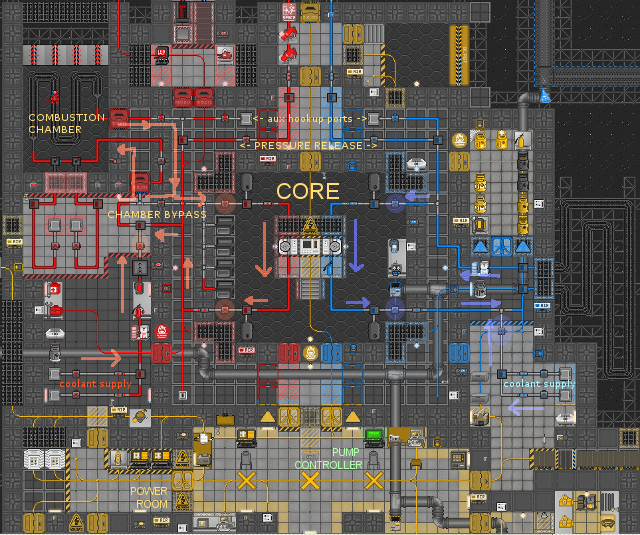

The engine has three segments: a Hot loop, filled with gas that takes heat from the furnaces, the combustion chamber, or even both. A cold loop that uses cold gas to draw heat from the hot loop. The generator which transfers heat from the hot to the cold loop and produces power.

Gas inside the pipes has two main property, pressure and temperature.

Pressure directs the gas flow, from higher to lower pressure pipe segments. When pressure in a loop is greater after the generator than it is before, gas flow stalls, and power output drops.

Too high pressure will cause pipes to burst!

Temperature will cause gas to increase or decrease in pressure. Very little gas, when heated can reach gigantic pressure.

Conversely, the cold loop will most often be at a low pressure, even when packed with gas.

The engine doesn't require incredible pressure to work correctly. Pressure must flow in the right direction, higher before the engine than it is after. Check the meters, and use your pda or an analyzer on a pipe to read its pressure.

Four pumps around the loop keep the gas flowing. Toggling their speed can help to regulate the power output, or fix a pressure imbalance that is blocking gas flow within a loop.

Each canister hookup has its own pump, to increase or decrease the speed of gas injection of into a loop.

Gas

Any gas can be used as a medium in both pipe loops; and each gas has a different ability to retain heat or transfer it more quickly. Generally, safer gases will yield much lower power outputs.

Experimenting with different gas in each loop will let you discover which combinations work best, and how to control the most dangerous gas.

Pressure

The engine can be efficiently run on very small quantities of gas. Filling the pipes with entire canisters of gas will increase the chance of pressure issues. Injecting small quantities of gas in the loops and the combustion chamber over time, reduces waste and allows for very high power outputs.

Too high pressure inside a pipe will cause it to fracture and leak gas. A broken pipe can be repaired by welding.

Pressure imbalances that stop the correct flow of gas can be controlled by venting gas (either to a canister, or to space). Venting is more effective when gas flow is temporarily blocked by shutting down the intake valve or reducing the pressure of the intake pump.